Laminate

介绍

Laminate类用于层合板校核分析,集成了Practical Micromechanics of Composite Materials一书中部分的开源代码$^{[1]}$。该类用经典的复合材料层合板理论进行校核,可以初步对层合板进行选型计算,但在实际工程中还是要考虑将实际几何和边界考虑进仿真中。

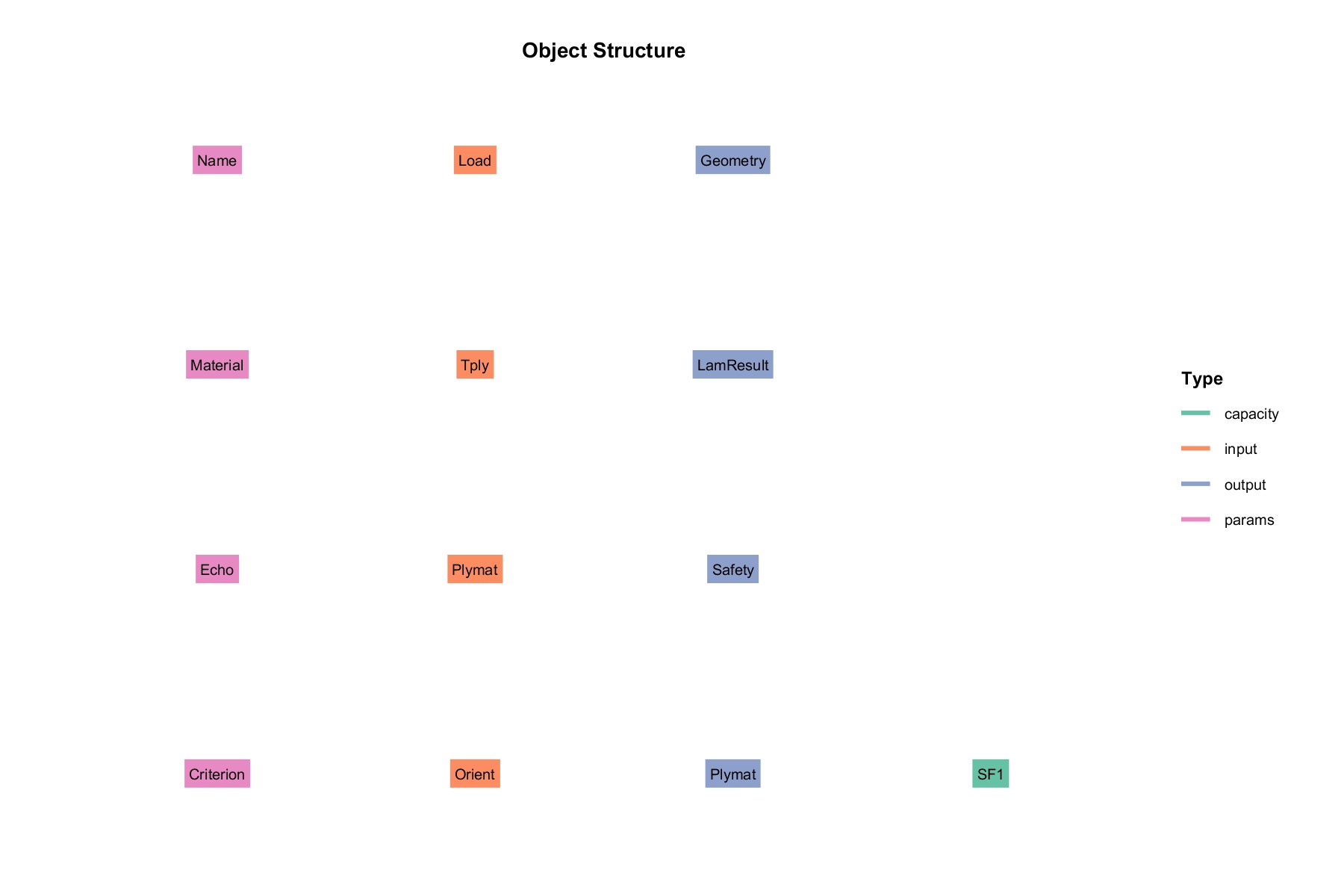

类结构

输入 input:

- Load : 载荷

- Tply : 铺层厚度

- Plymat : 铺层材料

- Orient : 铺层角度

参数 params:

- Name :名称

- Material : 材料

- Ctiterion : 失效准则

输出 output :

Geometry : 几何

LamResult : 壳单元装配

Safety : 截面

Plymat : 实体网格

能力 capacity :

- SF1 : 总体极限安全系数

案例

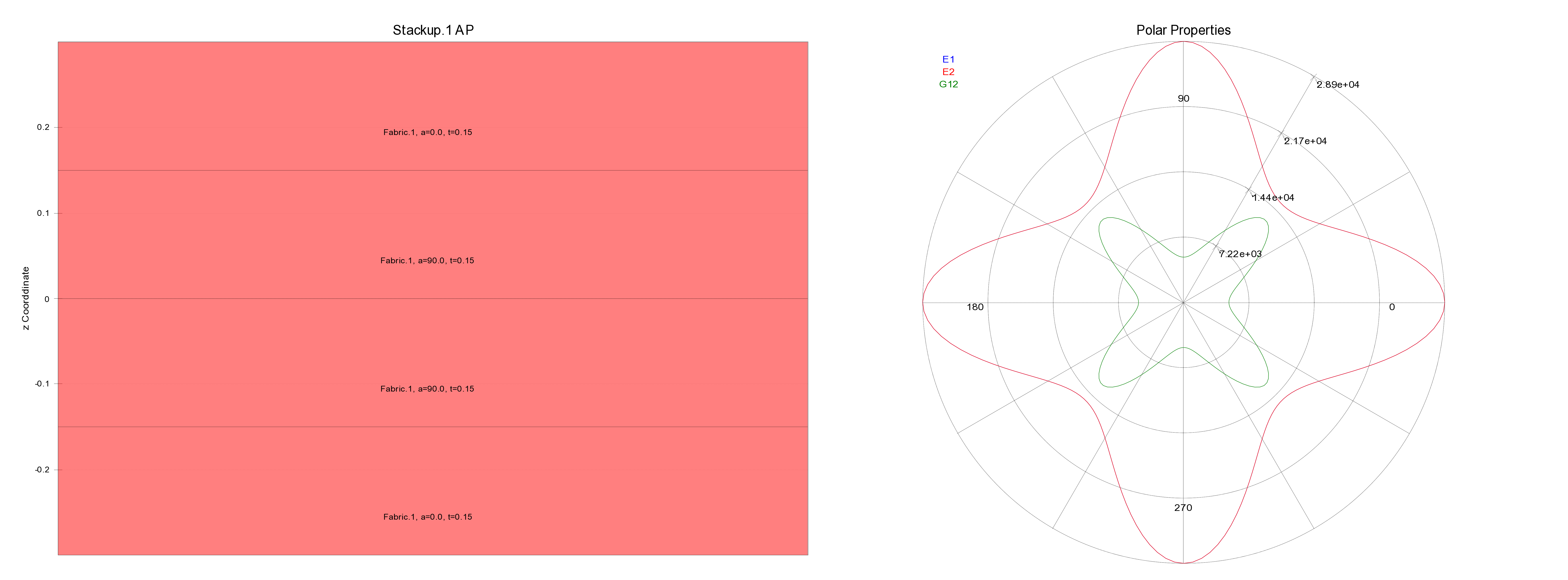

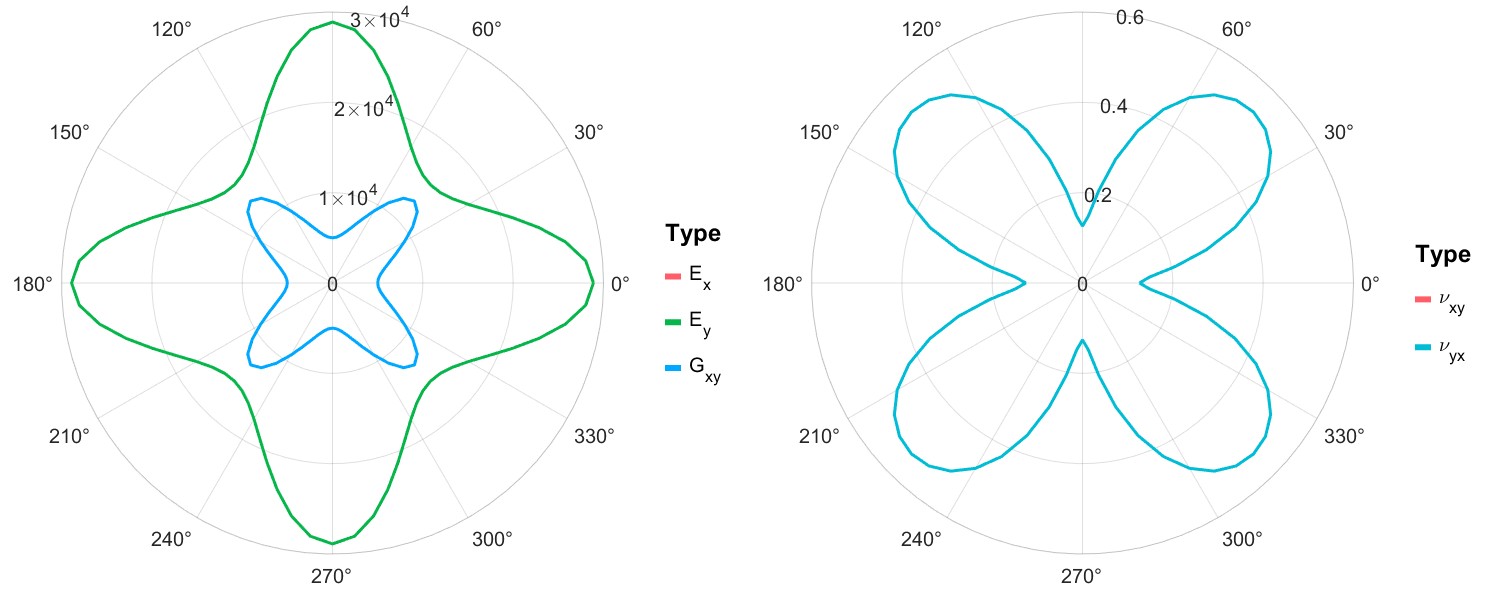

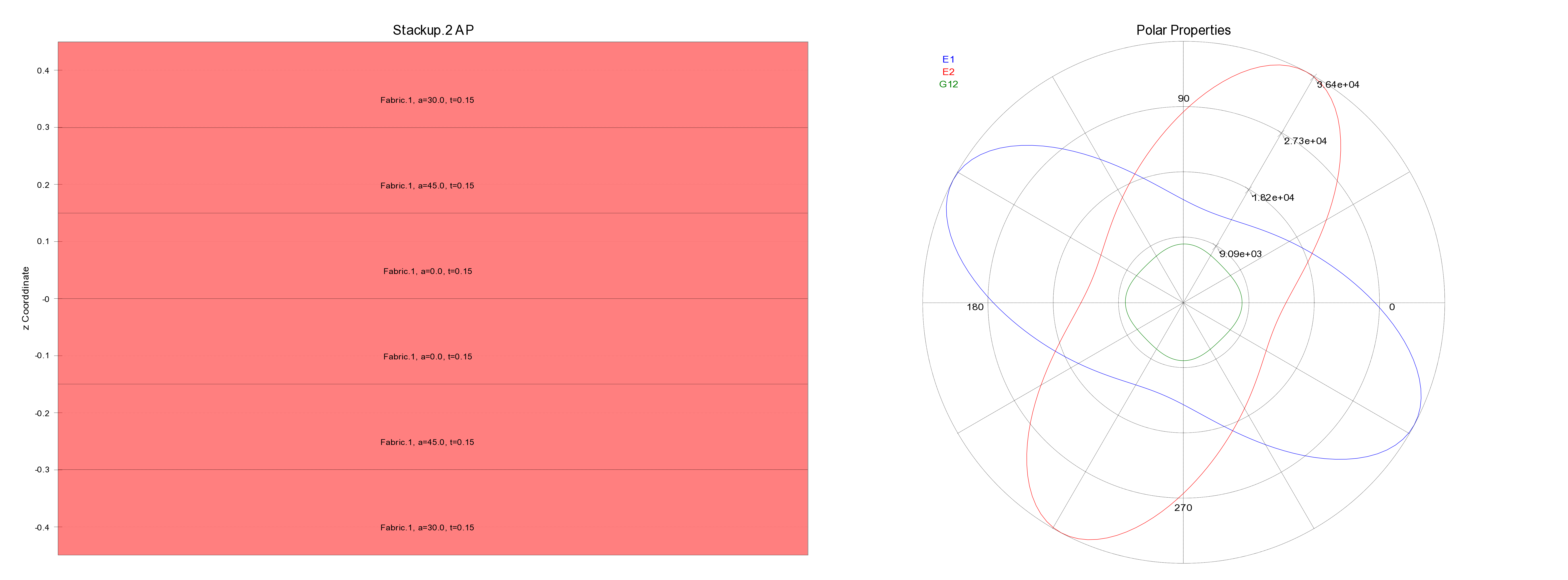

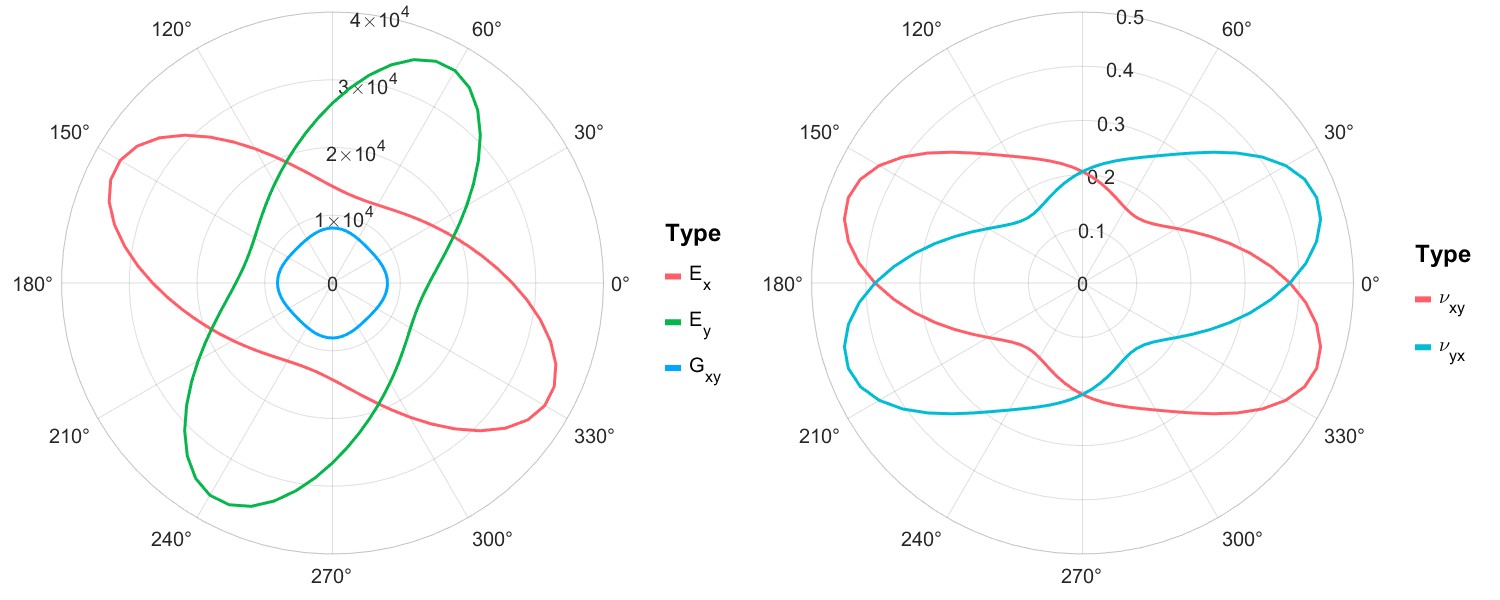

Compare to ANSYS ACP (Flag=1)

此案例用Workbench ACP和Laminate类比较了几种比较常见的铺层方式(对称、反对称等)下层合板宏观力学参数,材料属性为E-Glass/Epoxy, 参数如下。

| Density | Ex | Ey | Ez | Gxy | Gyz | Gxz | $\mu_{xy}$ | $\mu_{yz}$ | $\mu_{xz}$ |

|---|---|---|---|---|---|---|---|---|---|

| $t/mm^3$ | $MPa$ | $MPa$ | $MPa$ | $MPa$ | $MPa$ | $MPa$ | |||

| 1.987e-9 | 44000 | 13400 | 13400 | 5000 | 4600 | 5000 | 0.27 | 0.45 | 0.45 |

S=RMaterial('Composite');

mat=GetMat(S,5);

type=1;

switch type

case 1

% Symmetric layout 1

inputStruct.Orient=[0,90,90,0]';

inputStruct.Tply=repmat(0.15,4,1);

inputStruct.Plymat=ones(4,1);

case 2

% Symmetric layout 2

inputStruct.Orient=[30,45,0,0,30,45]';

inputStruct.Tply=epmat(0.15,6,1);

inputStruct.Plymat=ones(6,1);

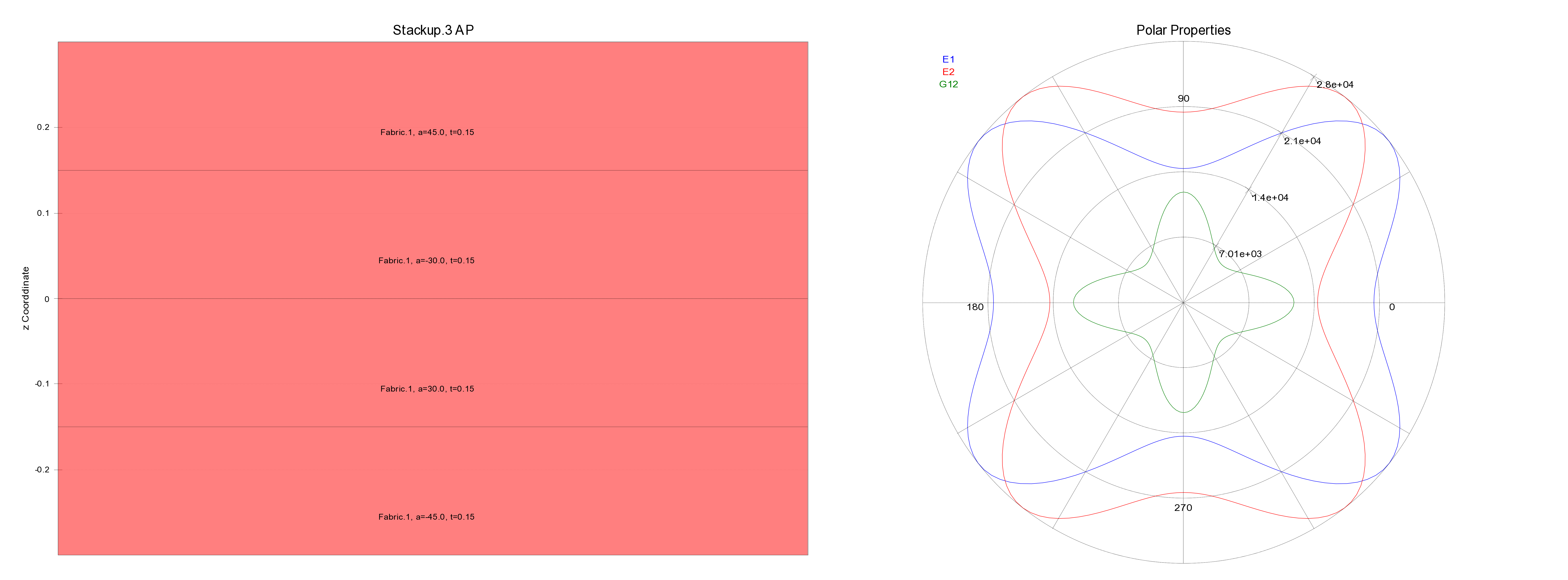

case 3

% Antisymmetric layout 1

inputStruct.Orient=[-45,30,-30,45]';

inputStruct.Tply=repmat(0.15,4,1);

inputStruct.Plymat=ones(4,1);

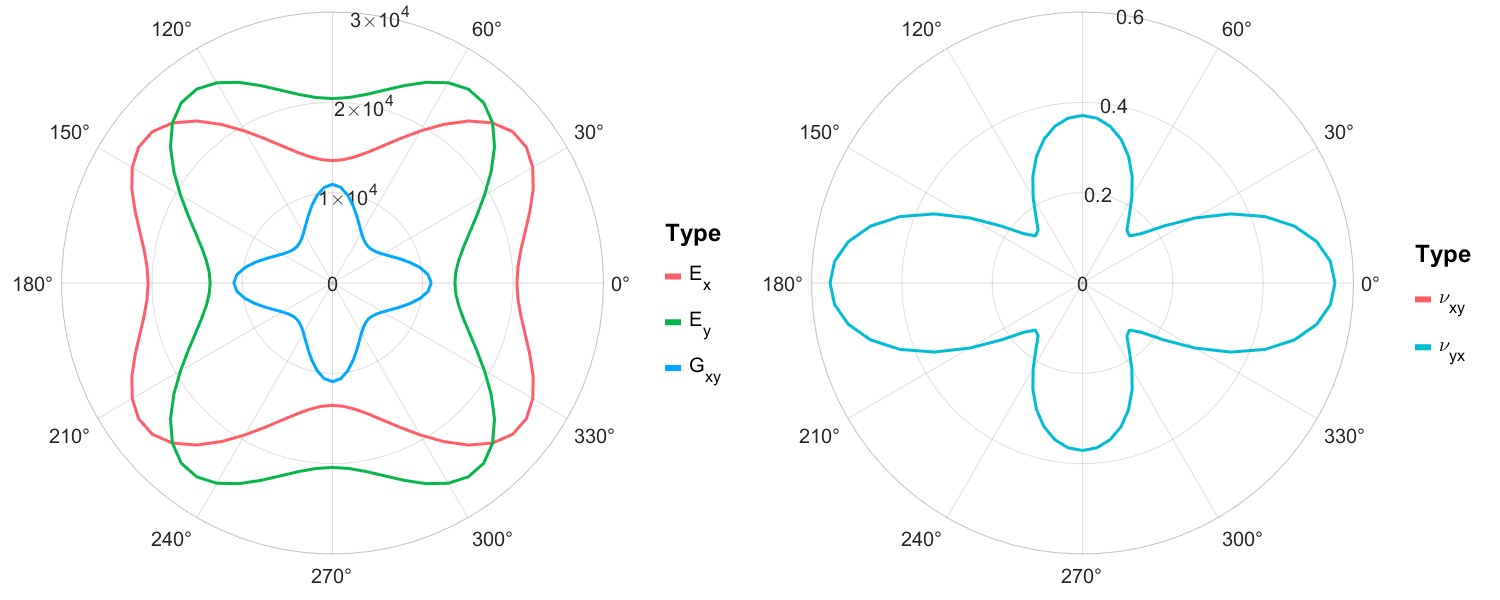

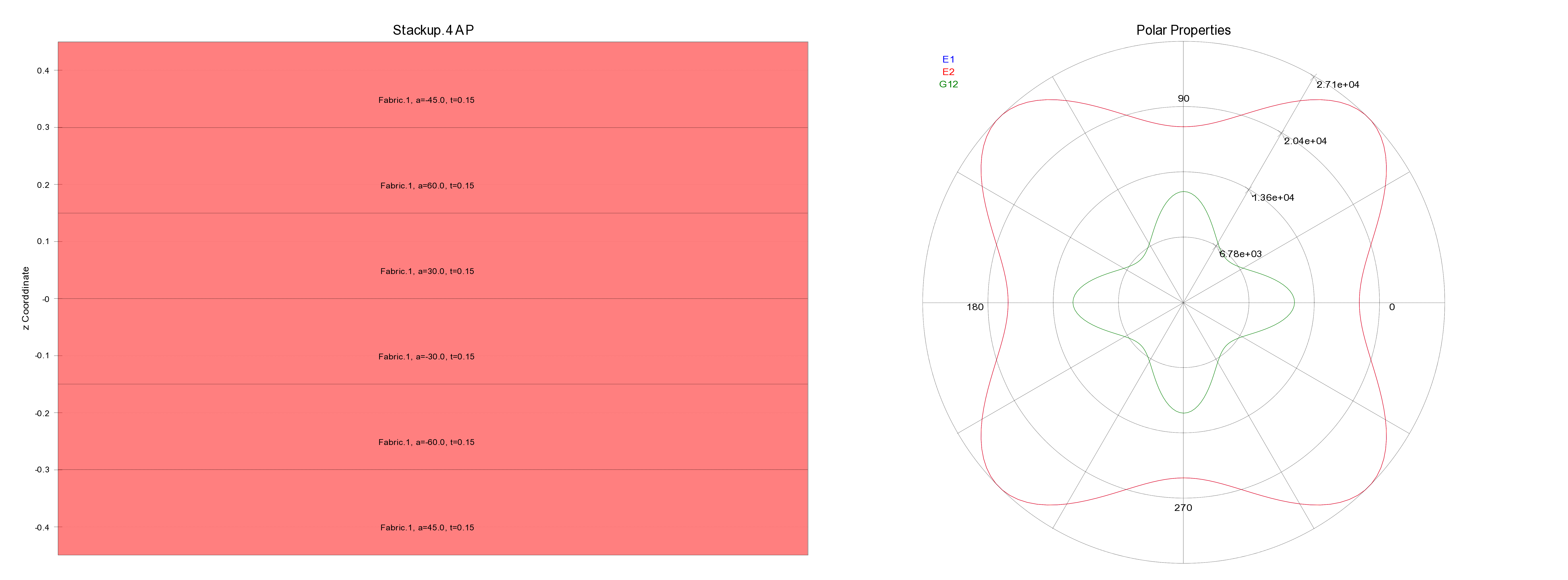

case 4

% Antisymmetric layout 2

inputStruct.Orient=[45,-60,-30,30,60,-45]';

inputStruct.Tply=repmat(0.15,6,1);

inputStruct.Plymat=ones(6,1);

end

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

inputStruct.Load.Value = [15, 0, 0, 0, 0, 0];

% inputStruct.Load.Value = [0, 0, 0, 15, 0, 0];

paramsStruct.Material=mat;

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

PlotResult(L);

PlotResult(L,'MC',1);

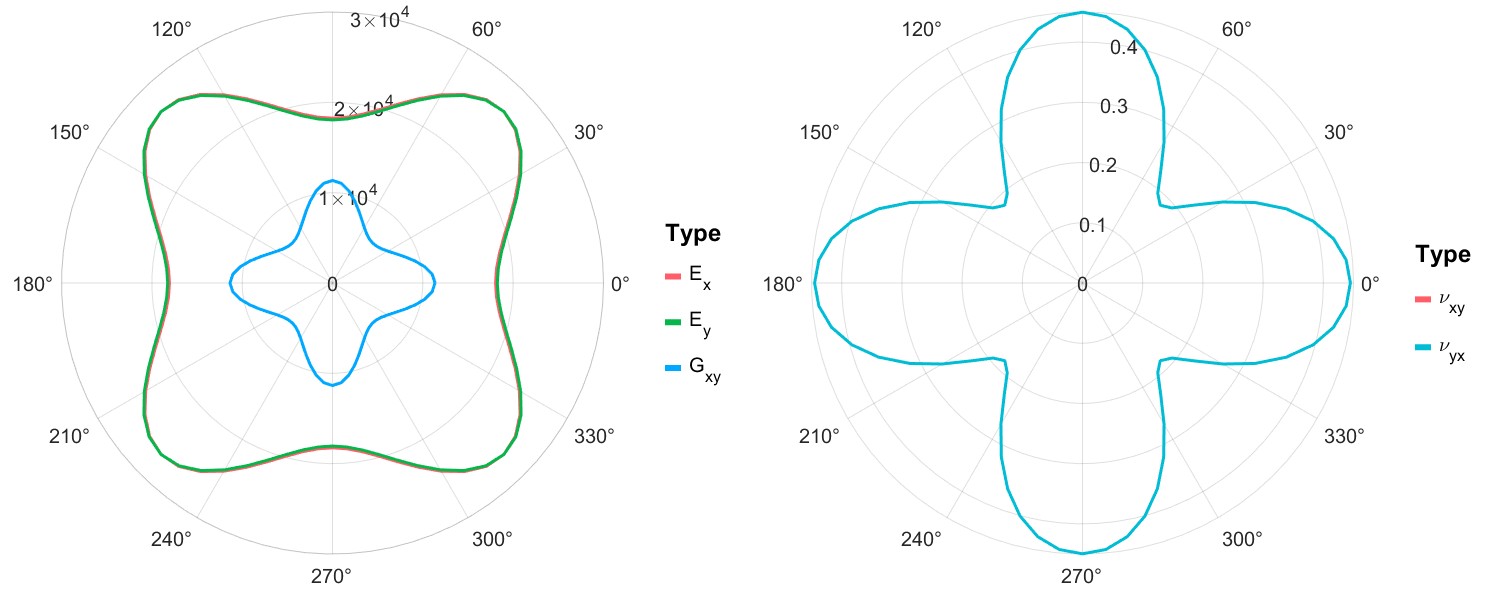

PlotLaminateProperty(L);

UD laminate with 45° (Flag=2)

S=RMaterial('Composite');

mat=GetMat(S,22);

inputStruct.Orient=45;

inputStruct.Tply=0.15;

inputStruct.Plymat=1;

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

inputStruct.Load.Value = [1, 0, 0, 0, 0, 0];

paramsStruct.Material=mat;

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

PlotResult(L);

A Matrix :.

1.0e+03 *

2.8580 1.8230 1.2236

1.8230 2.8580 1.2236

1.2236 1.2236 1.8656

B Matrix :.

0 0 0

0 0 0

0 0 0

D Matrix :.

5.3587 3.4181 2.2942

3.4181 5.3587 2.2942

2.2942 2.2942 3.4980

Laminate effective properties :.

Ex Ey Nuxy Gxy Alpha_x Alpha_y Alpha_xy.

10325.6102 10325.6102 0.496465246 8172.6842 1.792e-05 1.792e-05

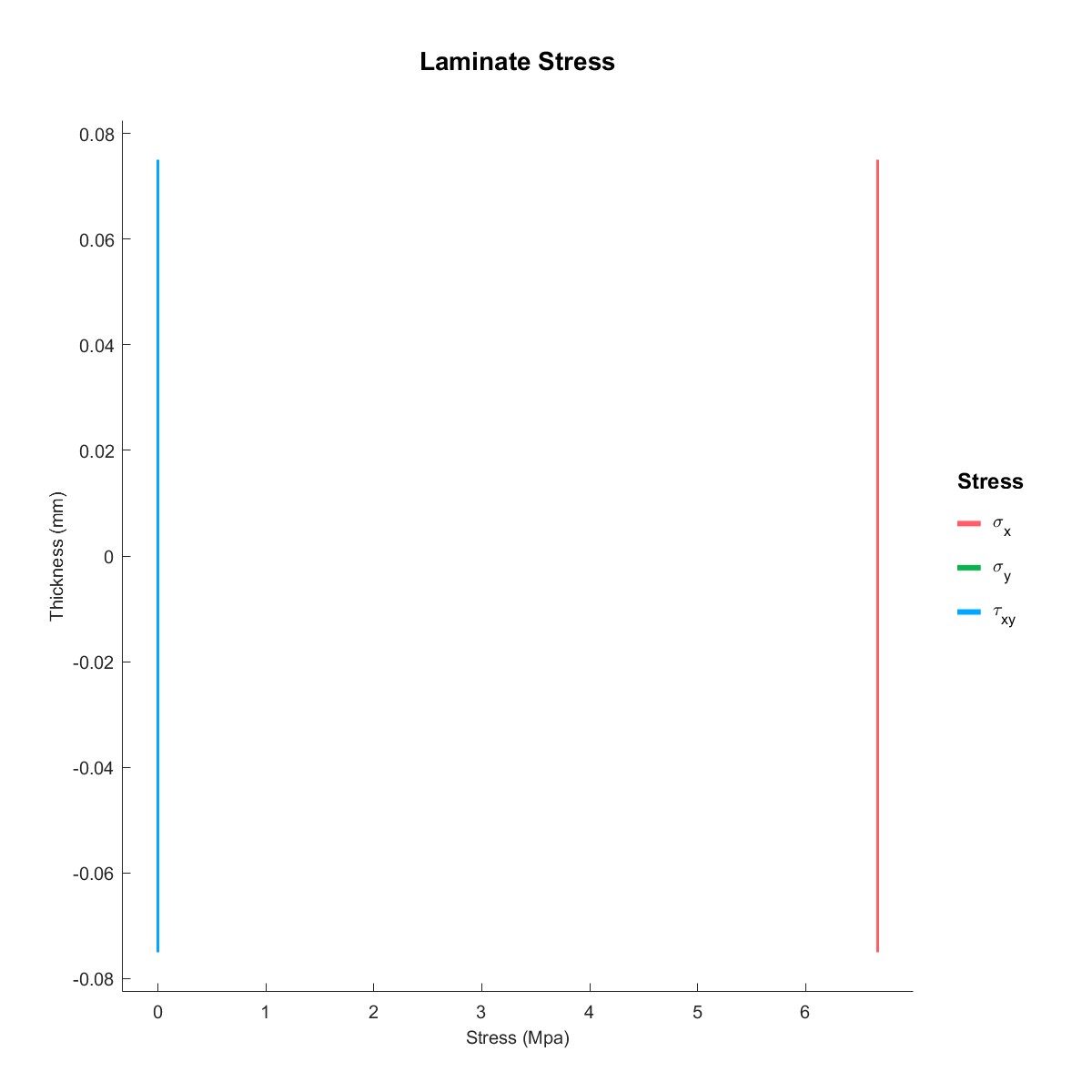

Cross ply (Flag=3)

S=RMaterial('Composite');

mat=GetMat(S,21);

type=3;

switch type

case 1

inputStruct.Orient=[0,90,90,0]';

case 2

inputStruct.Orient=[90,0,0,90]';

case 3

inputStruct.Orient=[0,0,90,90]';

end

inputStruct.Tply=repmat(0.15,4,1);

inputStruct.Plymat=ones(4,1);

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

% inputStruct.Load.Value = [1, 0, 0, 0, 0, 0];

inputStruct.Load.Value = [0, 0, 0, 1, 0, 0];

paramsStruct.Material=mat;

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

PlotResult(L);

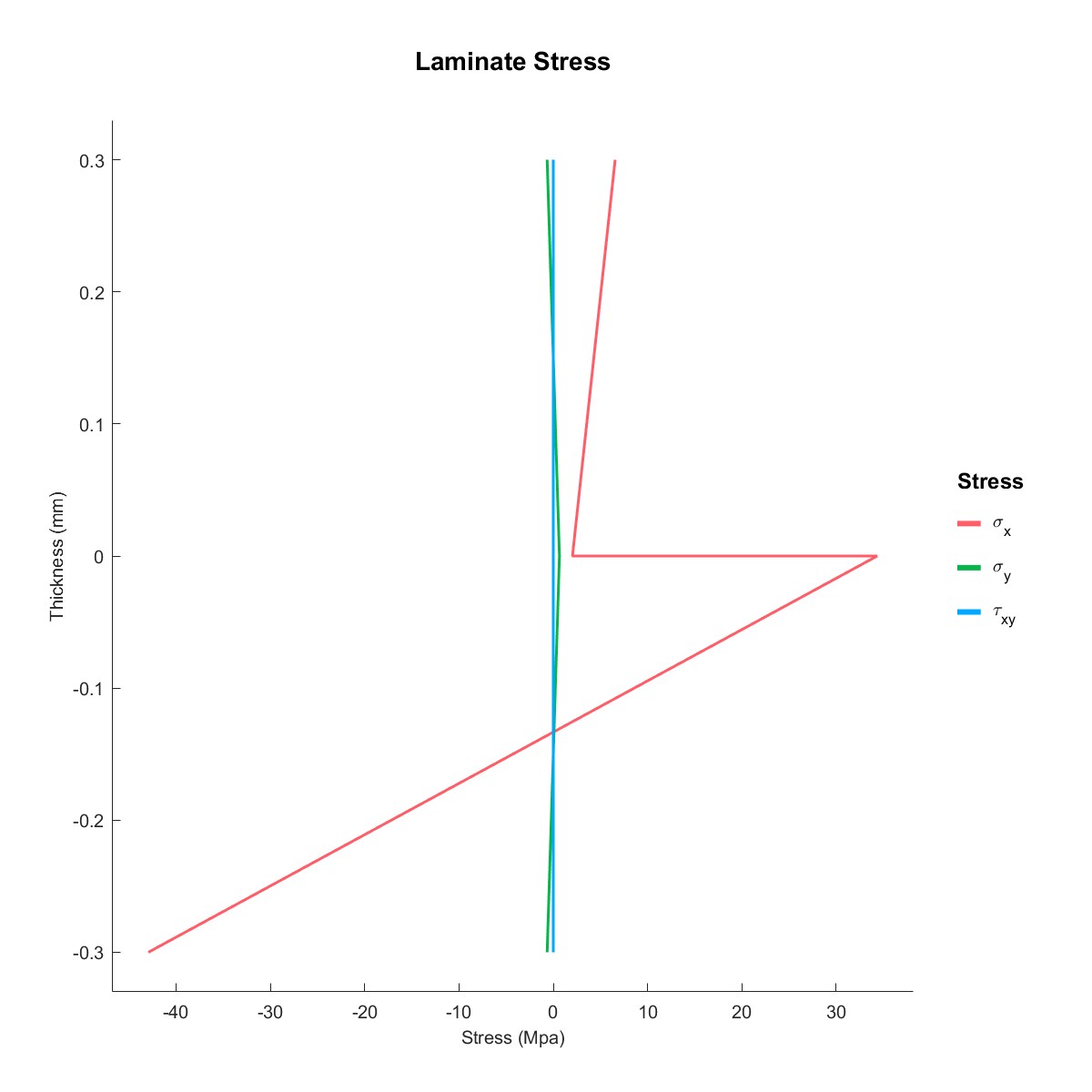

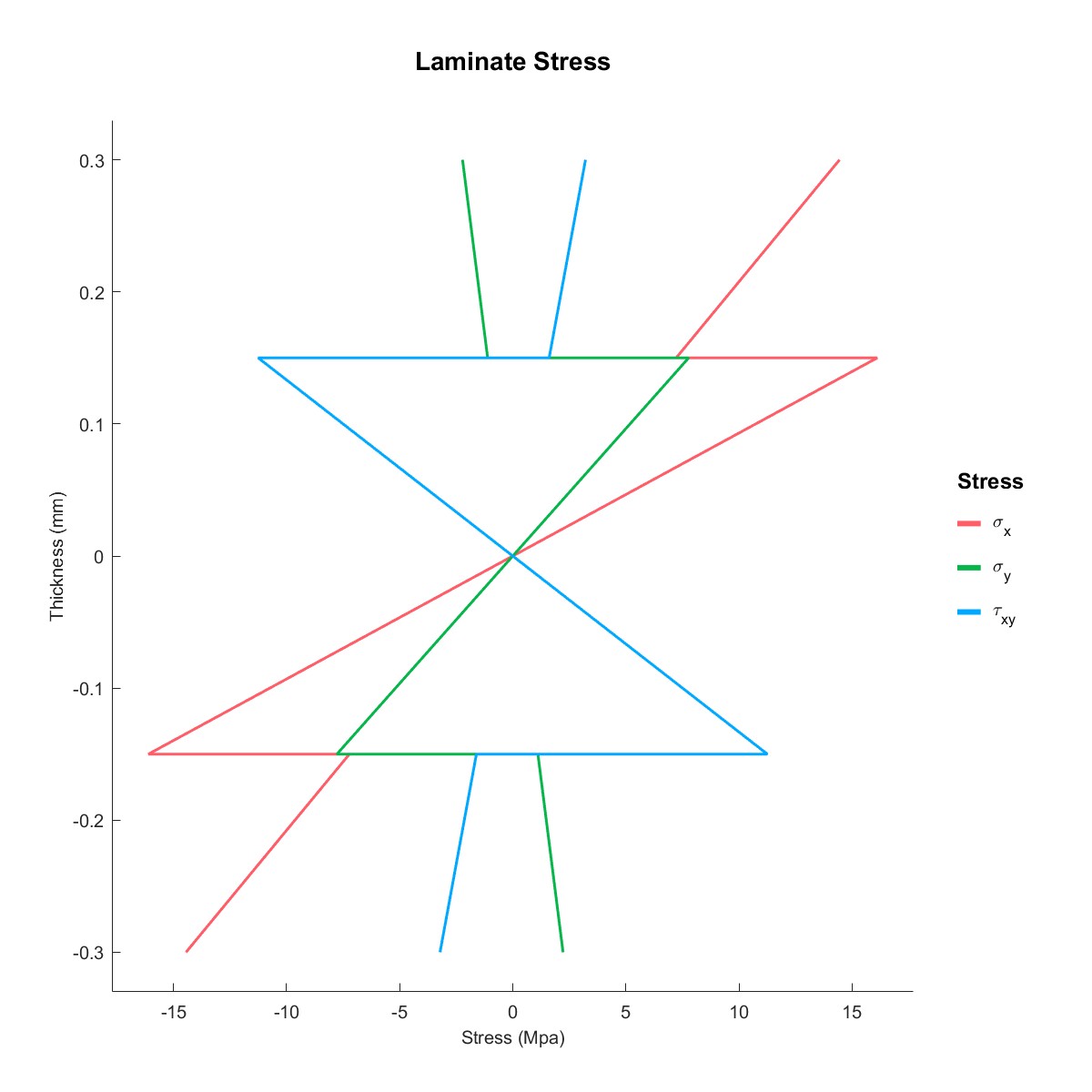

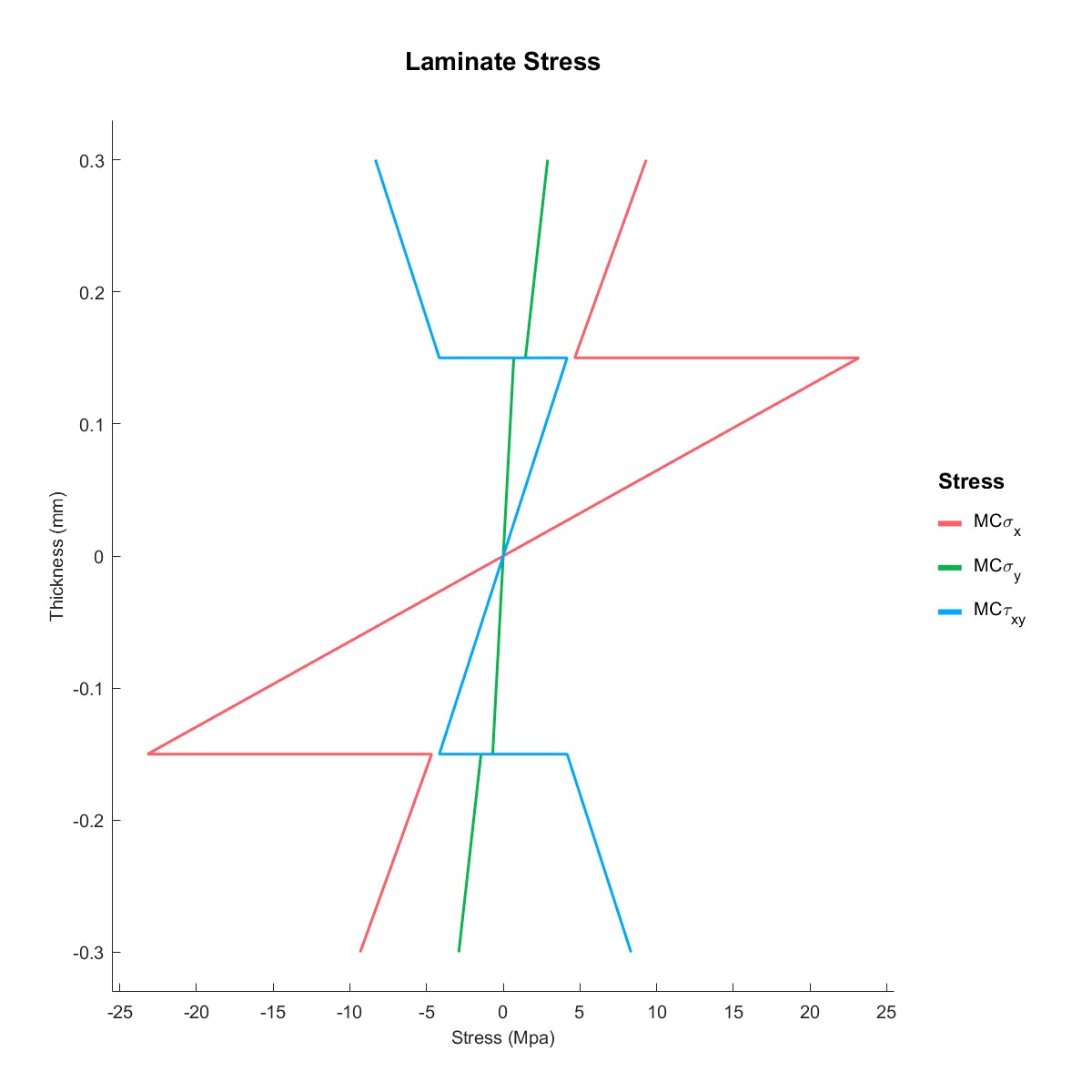

Plot material coordinate laminate results (Flag=4)

S=RMaterial('Composite');

mat=GetMat(S,21);

inputStruct.Orient=[45,-45,-45,45]';

inputStruct.Tply=repmat(0.15,4,1);

inputStruct.Plymat=ones(4,1);

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

inputStruct.Load.Value = [0, 0, 0, 1, 0, 0];

paramsStruct.Material=mat;

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

PlotResult(L);

PlotResult(L,'MC',1);

A Matrix :.

1.0e+04 *

2.7401 2.1209 0.0000

2.1209 2.7401 0.0000

0.0000 0.0000 2.2626

B Matrix :.

1.0e-12 *

-0.2274 0 0.2274

0 -0.2274 0.2274

0.2274 0.2274 -0.2274

D Matrix :.

822.0321 636.2721 468.9640

636.2721 822.0321 468.9640

468.9640 468.9640 678.7924

Laminate effective properties :.

Ex Ey Nuxy Gxy Alpha_x Alpha_y Alpha_xy.

18307.9217 18307.9217 0.774023421 37710.6905 2.11507815e-06 2.11507815e-06

|  |

Calculate UD lamminate failure Criterion (Flag=5)

S=RMaterial('Composite');

mat=GetMat(S,21);

type=2;

switch type

case 1

inputStruct.Orient=0;

inputStruct.Tply=1;

inputStruct.Plymat=1;

case 2

inputStruct.Orient=45;

inputStruct.Tply=1;

inputStruct.Plymat=1;

end

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

inputStruct.Load.Value = [1000, 0, 0, 0, 0, 0];

paramsStruct.Material=mat;

paramsStruct.Criterion=7;% Change method to get different results

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

PlotResult(L,'MC',1);

A Matrix :.

1.0e+04 *

4.5668 3.5348 3.4738

3.5348 4.5668 3.4738

3.4738 3.4738 3.7711

B Matrix :.

0 0 0

0 0 0

0 0 0

D Matrix :.

1.0e+03 *

3.8057 2.9457 2.8948

2.9457 3.8057 2.8948

2.8948 2.8948 3.1426

Laminate effective properties :.

Ex Ey Nuxy Gxy Alpha_x Alpha_y Alpha_xy.

12848.2864 12848.2864 0.244988988 7921.01413 1.545e-05 1.545e-05

Successfully add output geometry .

Successfully Calculate Laminate safety .

Laminate min MoS :

-0.9123

-0.9123

Laminate min SF :

0.0877

0.0877

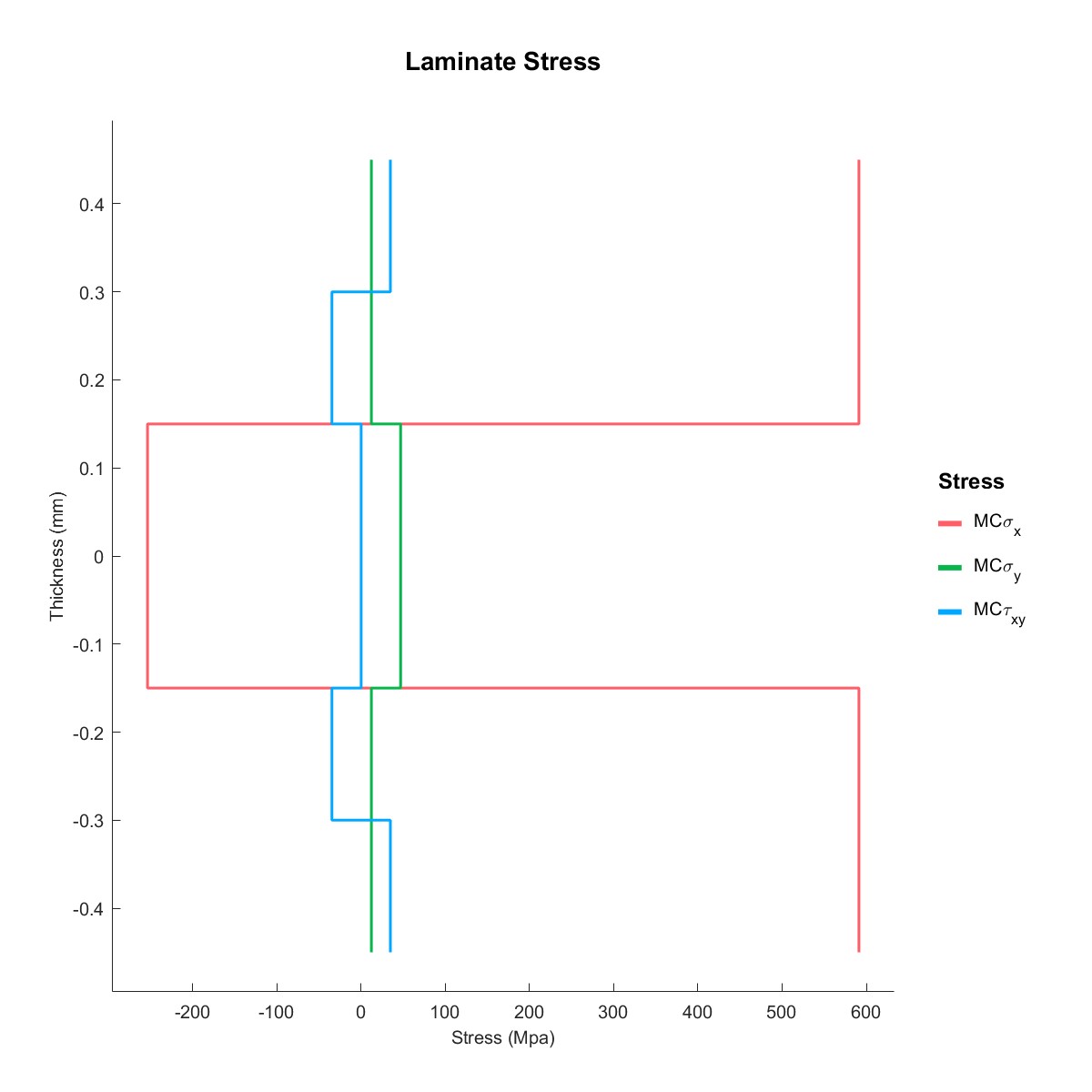

Calculate lamminate [60,-60,0]s failure Criterion (Flag=6)

S=RMaterial('Composite');

mat=GetMat(S,21);

inputStruct.Orient=[60;-60;0;0;-60;60];

inputStruct.Tply=repmat(0.15,6,1);

inputStruct.Plymat=ones(6,1);

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

% inputStruct.Load.Value = [300, 0, 0, 0, 0, 0];

inputStruct.Load.Value = [0, 300, 0, 0, 0, 0];

paramsStruct.Material=mat;

paramsStruct.Criterion=5;% Change method to get different results

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

PlotResult(L,'MC',1);

A Matrix :.

1.0e+04 *

5.5749 1.7166 -0.0000

1.7166 5.5749 -0.0000

-0.0000 -0.0000 1.9292

B Matrix :.

1.0e-12 *

-0.6821 0 0.3411

0.4547 0.9095 0.4547

0.3411 0.4547 0.4547

D Matrix :.

1.0e+03 *

1.4478 1.5981 0.4317

1.5981 5.1995 1.1928

0.4317 1.1928 1.7416

Laminate effective properties :.

Ex Ey Nuxy Gxy Alpha_x Alpha_y Alpha_xy.

56070.9982 56070.9982 0.307909847 21435.3452 2.11507815e-06 2.11507815e-06

Successfully add output geometry .

Successfully Calculate Laminate safety .

Laminate min MoS :

0.9730

0.9730

0.9730

0.9730

-0.0052

-0.0052

-0.0052

-0.0052

0.9730

0.9730

0.9730

0.9730

Laminate min SF :

1.9730

1.9730

1.9730

1.9730

0.9948

0.9948

0.9948

0.9948

1.9730

1.9730

1.9730

1.9730

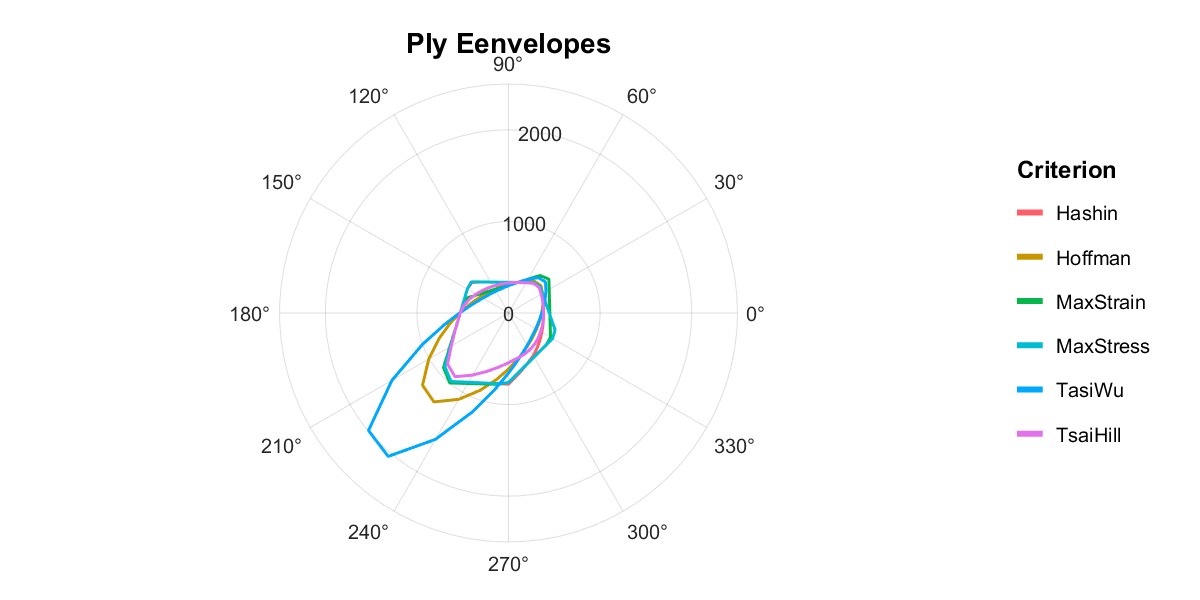

Ply-level failure envelopes (Flag=7)

S=RMaterial('Composite');

mat=GetMat(S,21);

Type=2;

switch Type

case 1

inputStruct.Orient=0;

inputStruct.Tply=1;

inputStruct.Plymat=1;

case 2

inputStruct.Orient=[60;-60;0;0;-60;60];

inputStruct.Tply=repmat(0.15,6,1);

inputStruct.Plymat=ones(6,1);

end

paramsStruct.Material=mat;

Env=NaN(37,6);

for i=1:37

theta=(i-1)*10;

inputStruct.Load.Type = [2, 2, 2, 2, 2, 2];

inputStruct.Load.Value = [cos(theta/180*pi), sin(theta/180*pi), 0, 0, 0, 0];

for j=1:6

paramsStruct.Criterion=j;

L= plate.Laminate(paramsStruct, inputStruct);

L=L.solve();

Env(i,j)=min(L.output.Safety.SFmin);

end

end

% Plot Env

x=0:360/36:360;

Env=mat2cell(Env',ones(1,6));

g=Rplot('x',x','y',Env,'Color',{'MaxStress','MaxStrain','TsaiHill','Hoffman','TasiWu','Hashin'});

g=geom_radar(g);

g=set_title(g,'Ply Eenvelopes');

g=set_names(g,'column','Origin','color','Criterion');

figure('Position',[100 100 800 400]);

draw(g)

参考文献

[1] Practical Micromechanics of Composite Materials

本网站基于Hexo 3-Hexz主题生成。如需转载请标注来源,如有错误请批评指正,欢迎邮件至 392176462@qq.com