介绍

OilSeal是骨架油封类,用于骨架油封的选型和计算。

原理

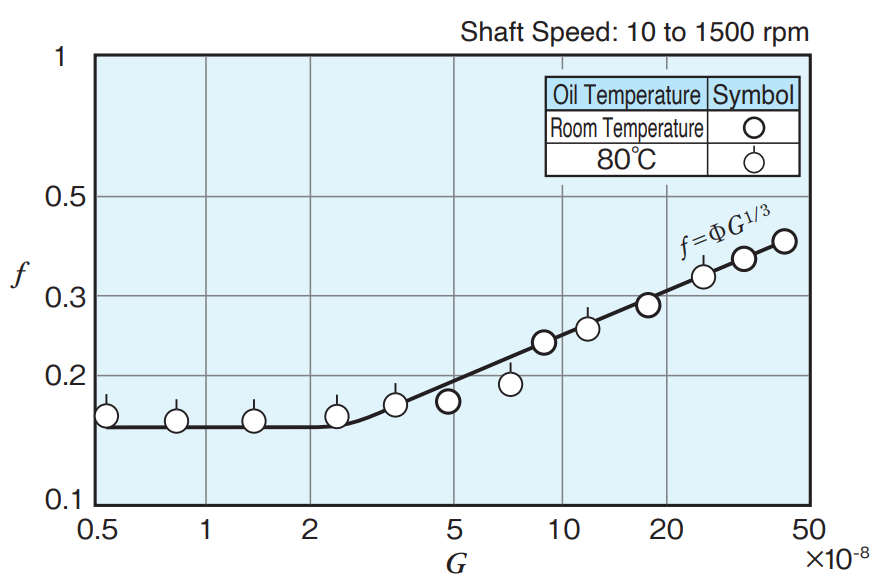

NOK摩擦系数计算方法

$$

f=\Phi G^{1/3}

$$

where

f = Coefficient of friction

$$\Phi$$ = An oil film condition constant

G = Non-dimensional duty parameter

$$

G=\mu ub/P_r

$$

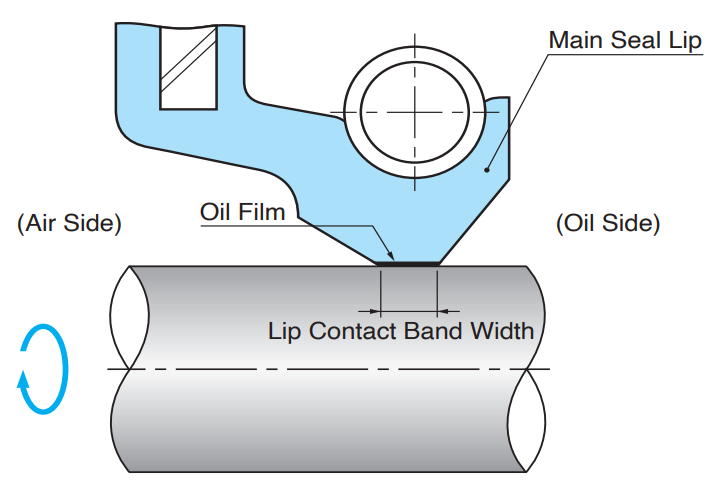

$P_r$ = Radial lip load on shaft (N)

$\mu$ = Oil viscosity ($N·s/cm^2$)

u = Linear shaft velocity (cm/s)

b = Lip-to-shaft constant band width (cm)

The positive slope area of the frictional properties has been explained by the lubrication theory. Under such lubrication conditions, the frictional property of seals is governed by the viscosity of the fluid and the shaft’s linear velocity (and is also identical to the frictional property of the bearing), and the resultant oil film present underneath the lip edge. In other words, the oil seal’s lip and the shaft slide against each other with an intervening film of oil, thus reducing wear.

$$

T=fP_rr

$$

T = Frictional torque (Ncm)

r= Radius of shaft (cm)

采用Getdata和Matlab对NOK手册中的参数f曲线进行拟合:

$$

\begin{equation}

f=\left{\begin{array}{lr}

0.15,G^{1/3}<0.029\

51.11·(G^{1/3}-0.0029)+0.15,G^{1/3}≥0.0029

\end{array}

\right.

\end{equation}

$$

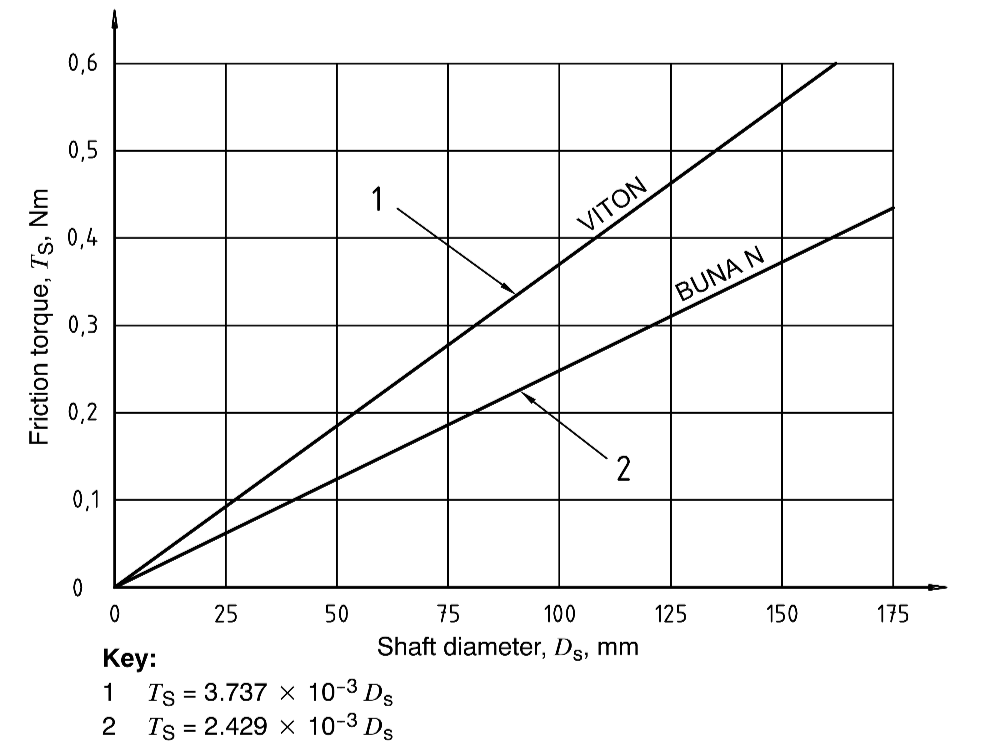

AGMA ISO 14179-1

$T_s$ = Oil seal Torque (Nm)

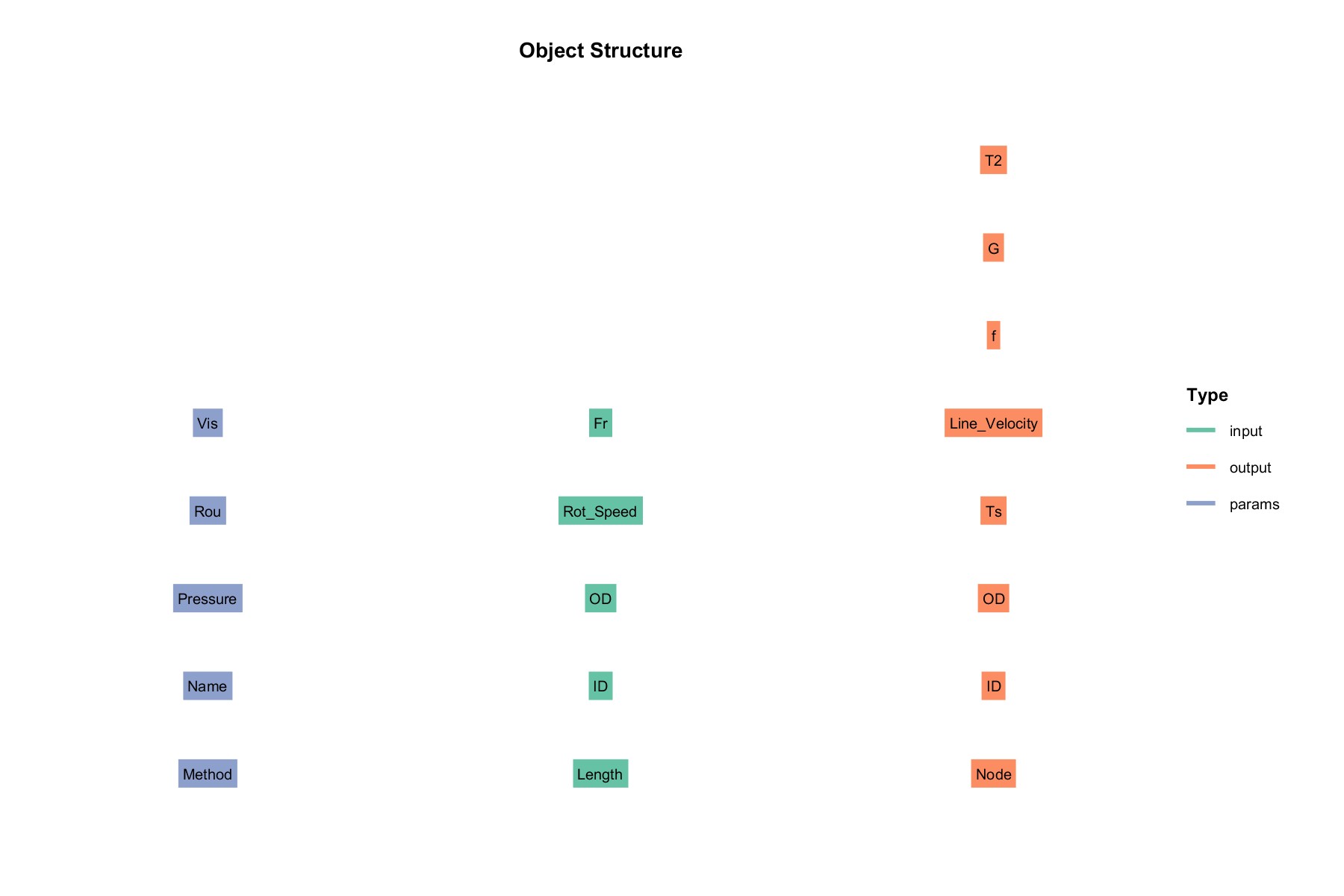

类结构

输入 input:

- Length : 油封长度

- ID : 油封内径

- OD : 油封外径

- Rot_Speed : 轴转速

- Fr : 唇口径向力

参数 params:

- Name : 名称

- Pressure: 油封唇口径向压力

- Rou : 润滑油密度

- Vis : 润滑油运动粘度

- Method : 计算方法

输出 output :

- Node : 输出节点

- ID : 输出内径

- OD : 输出外径

- Ts : 油封摩擦扭矩

- Line_Velocity : 油封线速度

- f : 唇口摩擦系数

- G :参数G

- T2 : 唇口温升

案例

Demo1 (Flag=1)

%% Defination the size of oil seal

inputStruct1.ID=50;

inputStruct1.OD=70;

inputStruct1.Length=10;

paramsStruct1.Name='Demo_OilSeal';

Oilseal1 = shaft.OilSeal(paramsStruct1, inputStruct1);

Oilseal1=Oilseal1.plot2D();

%% Oilseal frictional torque calculation

Oilseal1.input.Rot_Speed=1000;

Oilseal1=Oilseal1.cal_velocity();

Oilseal1=Oilseal1.cal_torque1();%According to AGMA ISO 14179-1

Torque1=Oilseal1.output.Ts;

disp(Torque1)

Oilseal1.params.Vis=10;

Oilseal1=Oilseal1.cal_torque2();%According to NOK

Torque2=Oilseal1.output.Ts;

disp(Torque2)

%% Oilseal temprature calculation

Oilseal1=Oilseal1.cal_T2();%According to NOK

%% Plot frictional torque&temperature curve

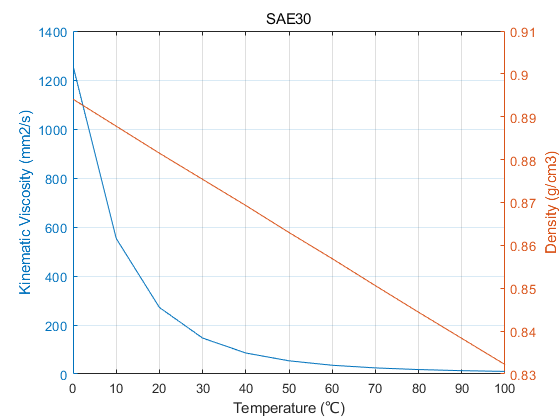

%SAE 30 measured data

T_SAE30=(0:10:100)';

Vis_SAE30=[1257.25;553.2;271.56;146.7;85.76;53.8;35.69;24.89;18.1;13.62;10.58];

Rou_SAE30=[0.8941;0.8878;0.8815;0.8754;0.8693;0.863;0.8569;0.8506;0.8444;0.8383;0.8322];

figure

yyaxis left

plot(T_SAE30,Vis_SAE30)

title('SAE30')

xlabel('Temperature (℃)')

ylabel('Kinematic Viscosity (mm2/s)')

yyaxis right

plot(T_SAE30,Rou_SAE30)

ylabel('Density (g/cm3)')

grid on

%calculate

Torque3=NaN(numel(T_SAE30),1);

for i=5:numel(T_SAE30)

Oilseal1.params.Vis=Vis_SAE30(i);

Oilseal1.params.Rou=Rou_SAE30(i)*1e-9;

Oilseal1=Oilseal1.cal_torque2();%According to NOK

Torque3(i)=Oilseal1.output.Ts;

end

figure

plot(T_SAE30(5:end,1),Torque3(5:end,1))

title('SAE30 Frictional Torque & Temperature curve')

xlabel('Temperature (℃)')

ylabel('Ts (Nmm)')

grid on

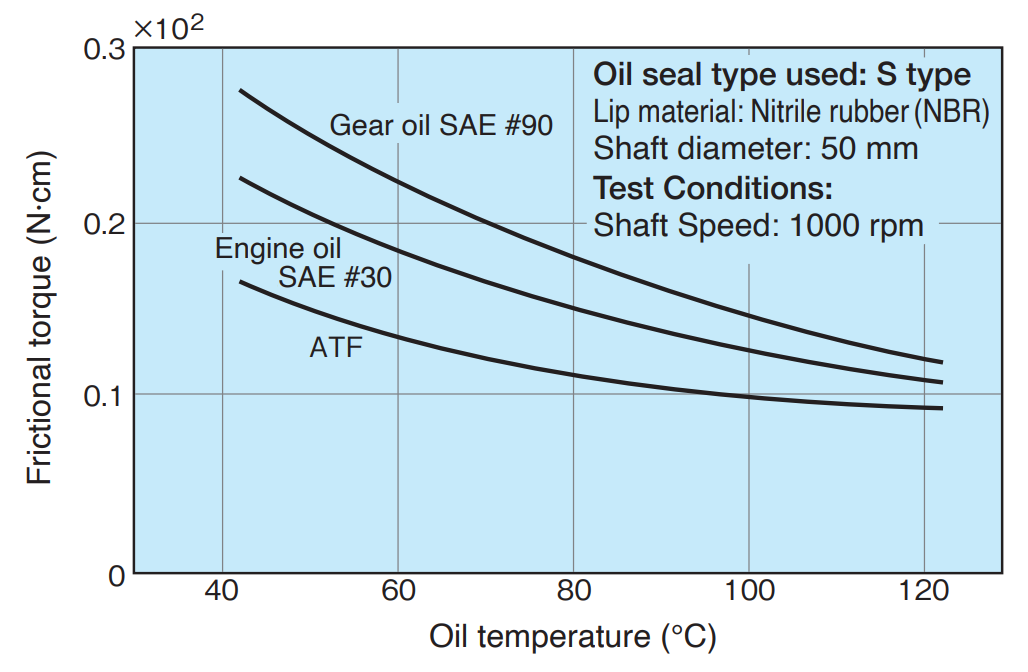

下图为NOK手册中计算SAE30机油摩擦扭矩和油温的关系曲线:

采用Matlab计算,取SAE30的粘度和密度曲线如下:

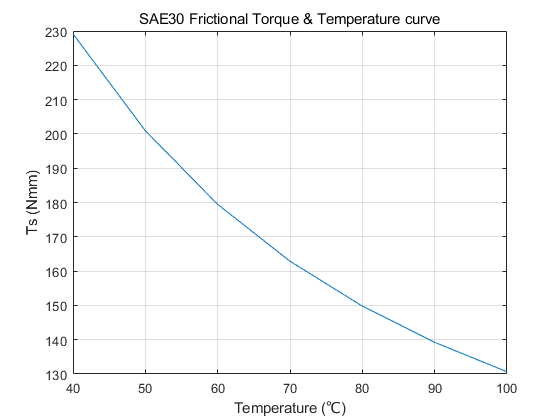

经计算得到的摩擦扭矩如下所示,可以看出计算值跟NOK手册中的值基本一致。而采用ISO 14179-1的计算方法计算,其值随温度不变化,为恒定121.45Nmm,该值相对于NOK方法计算偏小。

参考文献

[1] NOK油封手册

[2] AGMA ISO 14179-1

本网站基于Hexo 3-Hexz主题生成。如需转载请标注来源,如有错误请批评指正,欢迎邮件至 392176462@qq.com