介绍

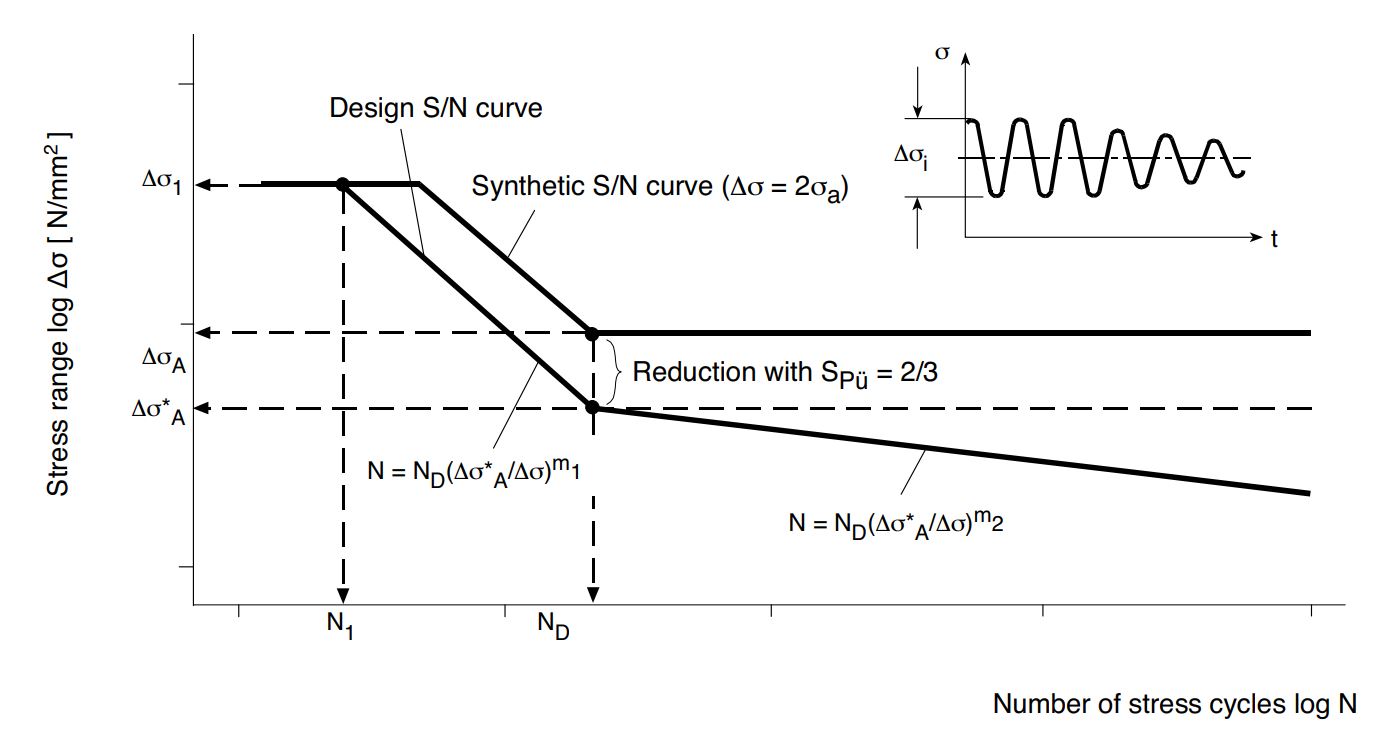

DNVGL_0361参照DNV规范给出合成SN曲线。

原理

S/N curves for cast steel, cast, forged and rolled parts

Reducing influences: The following reducing influences on the fatigue resistance shall be considered:

— type of loading

— significant residual stresses (e.g. shot peening, plastifications)

— stress ratio

— stress concentration factor

— notch effect factor

— component size

— surface quality

— influence of technological parameters

— survival probability

— environmental conditions (corrosion etc.).

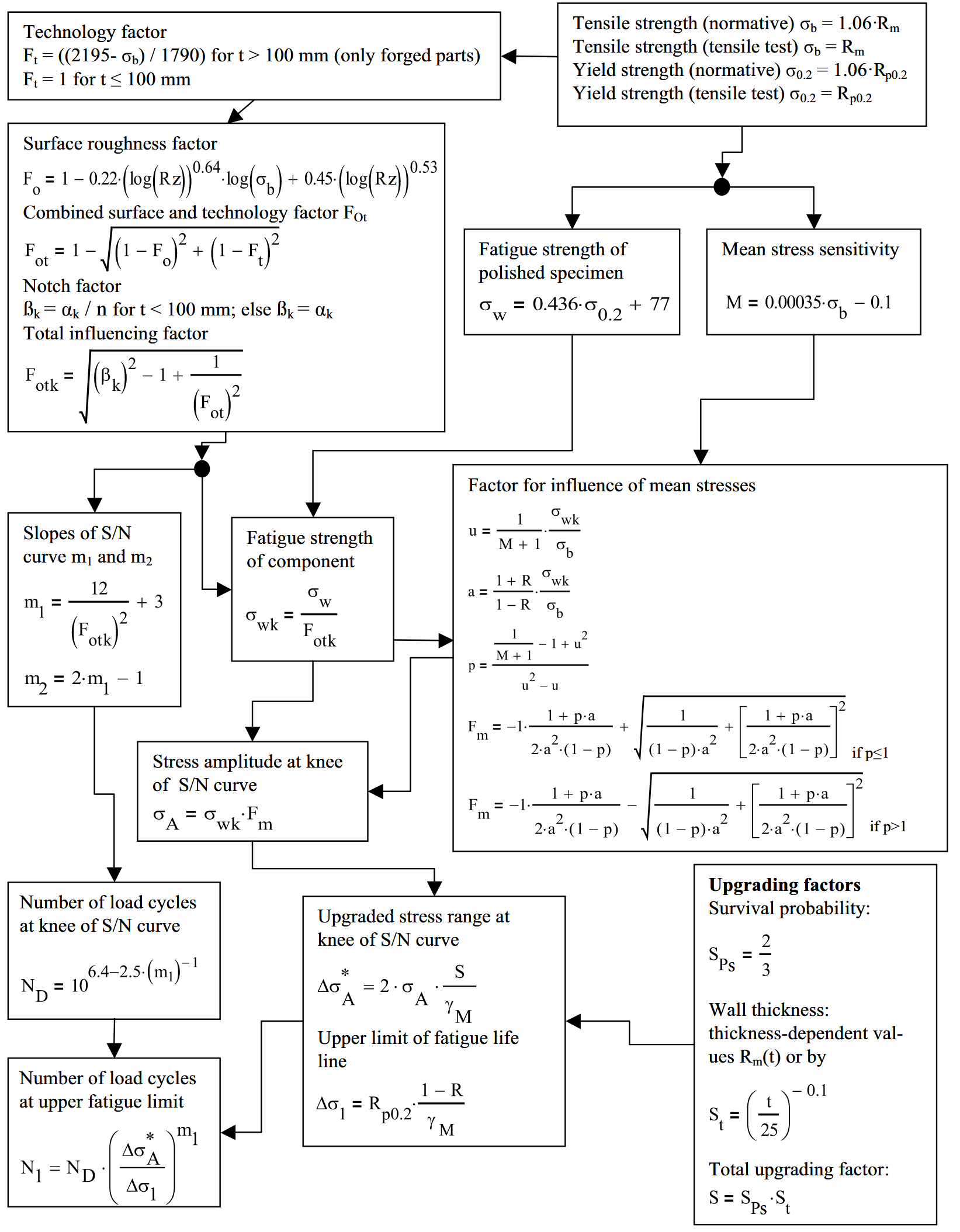

Survival probability: Usually, S/N curves are assigned a survival probability of P s = 50%. The fatigue analysis shall be performed with a survival probability of P > 97.7%. Unless determined otherwise, the S/N curve reference value Δ σ A shall be reduced to

$Δ_σ * A = Δ σ_A ∙ S_{Ps}$ where $S_{Ps} = 2/3$

which corresponds to a survival probability of P s > 97.7%. If S/N curves with a survival probability of P s > 50% are used, a reduction factor S Ps > 2/3 maybe assumed after consultation with DNV GL.

Admissible stress range: The fatigue strength line of the S/N curve shall be limited by the elastic properties of the material including the partial safety factor for material $γ_M$ . The respective mean stress level shall be considered when determining the upper limit of the fatigue strength line.

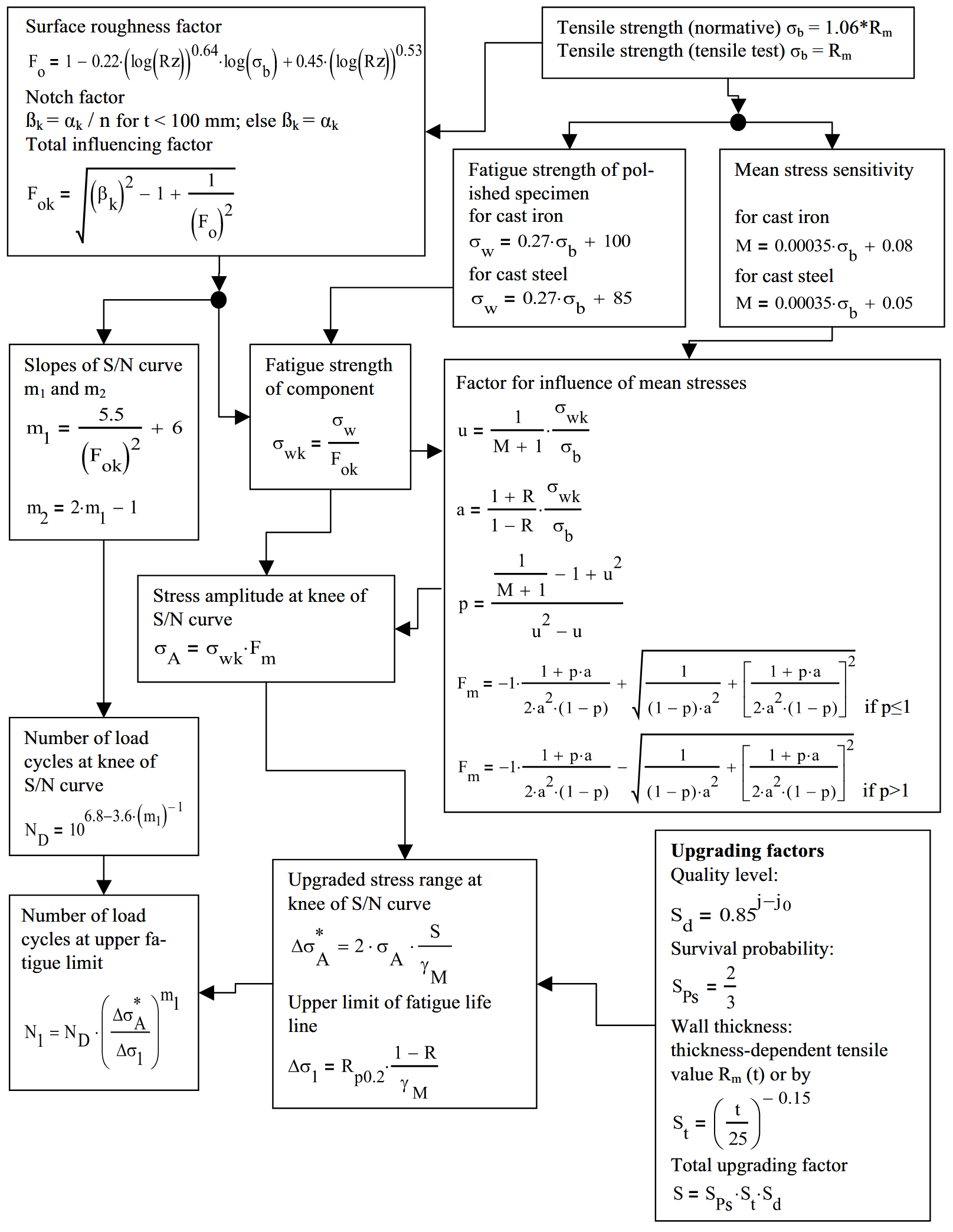

Reduction factors: The influence of large wall thicknesses and surface roughness shall be taken into account.

In the case of S/N curves determined from specimens taken from equally thick component regions, the influence of large wall thickness is included in the S/N curves.

When determining synthetic S/N curves , both the thickness-dependent mechanical characteristic values (guaranteed minimum tensile strength and yield point) as well as the reduction through the existing surface roughness shall be observed.

The assumed surface roughness for the determination of the S/N curve shall be consistent with the specified surface roughness.

Stress cycle numbers: For stress cycle numbers $N_i > N_D$ , the S/N curves shall be extended from $Δ σ * A$with the slope parameters $2m_1 -1$, where $m_1$ is the slope parameter of the fatigue strength line. Here the limiting stress cycle number $N_D$ is that number at which, under optimum test conditions (no corrosion effect, etc.), the endurance limit is given. Where synthetic S/N curves are used, $N_D$ results from its calculation.

In case of unfinished (raw and cleaned) casting surfaces a value of at least R z = 200 µm shall be assumed for the calculation, if no other value is specified.

In using synthetic S/N curves for cast iron, the influence of the quality levels and shall be considered through the factor

$$

S_d=0.85^{(j-j_0)}

$$

where:

For the assessment of the casting and surface quality and the testing techniques to be applied. MT/PT quality level is limited to level 3 in general. For the UT quality level 1 area, MT/PT quality level will be limited to level 2. This will ensure that, in the UT quality level 1 area, the more critical surface flaws detected by MT/PT are not allowed to be bigger than internal flaws detected by UT.

The classification into quality levels shall be documented consistently in the drawings, calculations and specifications and submitted to DNV GL for assessment within the scope of the design assessment and associated inspections.

Design S/N curve for cast material: The reference stress range to be used as a basis for the S/N curve is

$$

\Delta \sigma^{A}=S{Ps}S_d\Delta \sigma_A

$$

as the ideal fatigue limit at the stress cycle number $N_D$. For stress cycle numbers $N > N_D$, the S/N curves shall be extended from $Δ σ^_A$ with the slope $2m_1 -1$, where $m_1$ is the slope parameter of the fatigue strength line.

Non-welded forged and rolled parts

Cast steel and spheroidal graphite cast iron

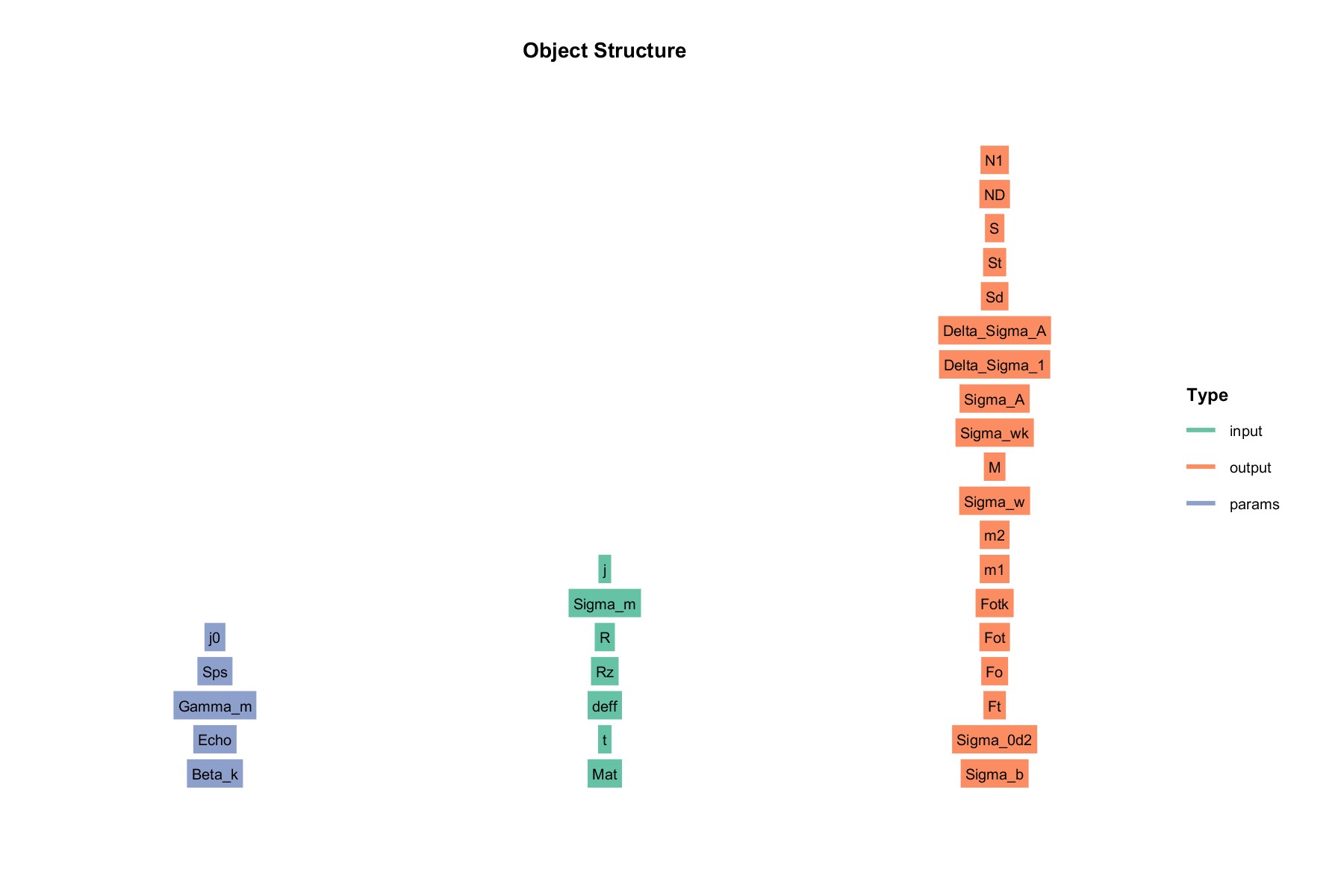

类结构

输入 input:

- Mat : 材料属性

- t : 厚度

- deff : 有效直径

- Rz : 表面粗糙度

- R : 应力比

- Sigma_m : 均值

- j : 质量参数

参数 params:

- Beta_k : 缺口系数

- Gamma_m : 材料安全系数

- Sps : 存活率

- j0 : 质量参数

输出 output :

Sigma_b : Tensile strength (normative) [MPa]

Sigma_0d2 : Yield strength (normative) [MPa]

Ft : Technology factor

Fo : Surface roughness factor

Fot : Combined surface and technology factor

Fotk : Total influencing factor

m1 : Slope1 of SN curve

m2 : Slope2 of SN curve

Sigma_w : Fatigue strength of polished sprcimen [MPa]

M : Mean stress sensitivity

Sigma_wk : Fatigue strength of component [MPa]

Sigma_A : Stress amplitude at knee of S/N curve [MPa]

Delta_Sigma_1 : Upper limit of fatigue life [MPa]

Delta_Sigma_A : Upgraded stress range at knee of S/N curve [MPa]

Sd : Quality level

St : Wall thickness-dependent values

S : Total upgrading factor

ND : Number of load cycles at knee of S/N curve

N1 : Number of load cycles at upper fatigue limit

案例

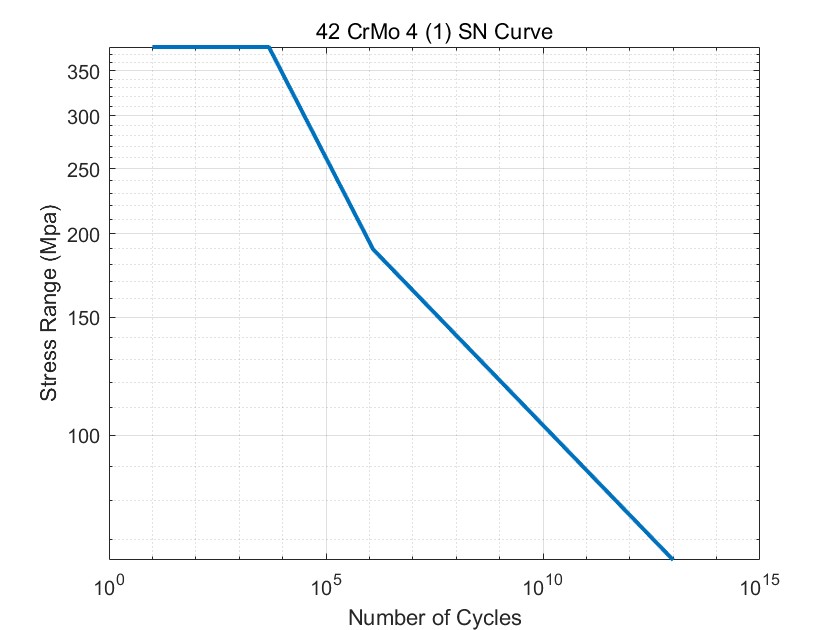

Create non-welded forged and rolled SN curve (Flag=1)

S=RMaterial('Basic');

Mat=GetMat(S,20);

inputStruct.Mat=Mat{1,1};

inputStruct.deff=200;

inputStruct.Rz=30;

inputStruct.R=0.1;

inputStruct.Sigma_m=150;

paramsStruct=struct();

SNCurve= method.DNVGL_0361(paramsStruct, inputStruct);

SNCurve= SNCurve.solve();

Plot(SNCurve);

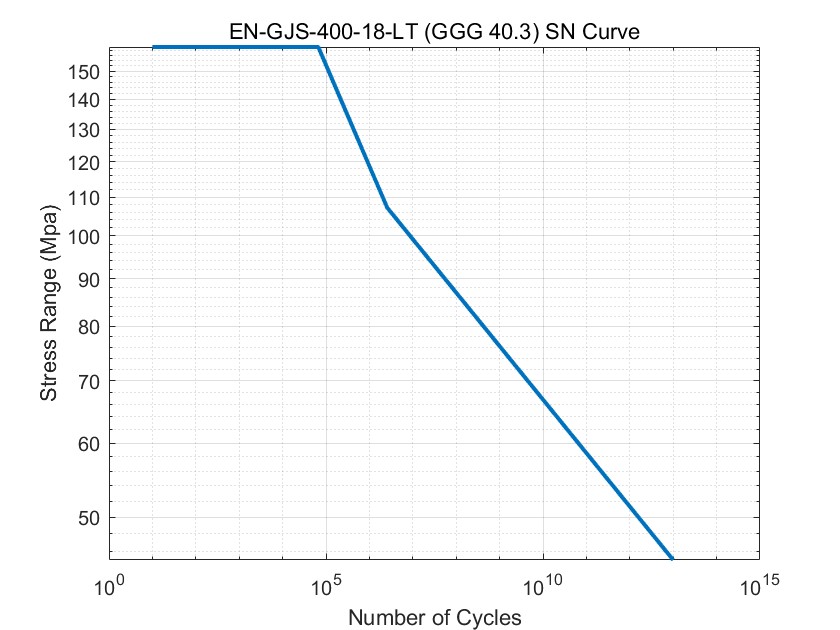

Create spheroidal graphite cast iron SN curve (Flag=2)

S=RMaterial('Basic');

Mat=GetMat(S,60);

inputStruct.Mat=Mat{1,1};

inputStruct.deff=200;

inputStruct.Rz=85;

inputStruct.R=0.1;

inputStruct.Sigma_m=82;

inputStruct.j=2;

paramsStruct=struct();

SNCurve= method.DNVGL_0361(paramsStruct, inputStruct);

SNCurve= SNCurve.solve();

Plot(SNCurve);

参考文献

[1] DNVGL-0361

本网站基于Hexo 3-Hexz主题生成。如需转载请标注来源,如有错误请批评指正,欢迎邮件至 392176462@qq.com